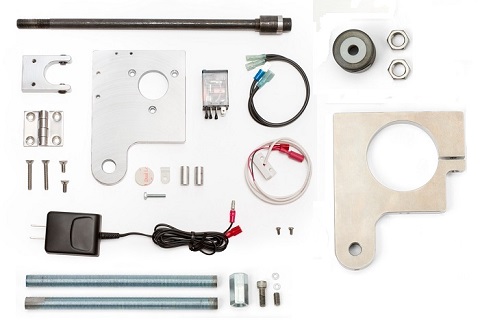

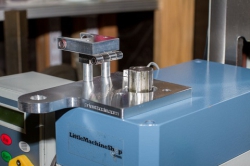

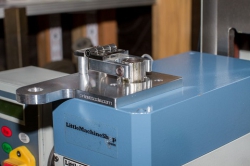

Productivity Upgrade Package, HiTorque Bench Mill

- Incluces both the 5655 Spindle Lock and the 5633 Quill Stop in one easy, one-stop package.

- Set accurate and consistent depth of cut for repeated machining operations.

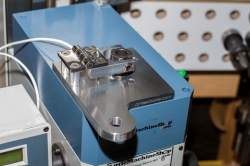

- Electro-magnetic interlock disables power to the motor with the fork of the Spindle Brake engaged.

- Quick and accurate way to set quill depth of cut on 5500 Bench Top Mill.

- PLEASE CHECK COMPATABILITY BEFORE ORDERING

To operate, flip the Spindle Brake fork down over the spindle while the spindle is at rest. Then rotate the spindle by hand until the set screws in the Spindle Brake fork mesh with a spindle spline. Once the tool change is complete, lift the Spindle Brake fork up into the retracted position and you are ready to go.

The Quill Stop provides a quick and accurate way to set the quill depth of cut. It is great for drilling multiple holes to the same depth. The Quill Stop is also very handy in performing single or repeated chamfering of parts. To set up the chamfer the first time on a part, turn the mill off and simply lower the cutter to the top of the part, lock the fine feed knob, and back-off one full turn (turn the Button Nut clockwise as viewed from the top). Then start the mill and turn the Button Nut on the Quill Stop counter clockwise in small increments until the cutter contacts the part. Then continue turning the Button Nut counterclockwise and alternately lowering the quill until the desired chamfer is achieved.

The Quill Stop works equally well performing inside chamfers using typical chamfering mills, and outside chamfers using, for example, a hollow mill.

Chris' Tips

Chris' TipsSimply press the button and the nut disengages from the thread

Slide to desired position and release the button to engage the threads

Turning the nut then allows for precision micro‐adjustments of depth of cut

Here are the Spindle Lock installation instructions.

- Integral Safety Switch and hand-retractable Spring Plunger

- Approximate dimensions and weight: 5.75l x 3.75w x 1.38"h, 2 lbs.

- The Spindle Brake plate, block, and fork are made of 6061-T6511 Aluminum

- The hinge and fasteners are made of Stainless Steel

- Installs in minutes

- Made to exacting specifications in precision machining centers in the USA

Compatibility

This product works with the following mills. (If your machine is not on this list, we cannot verify compatibility.)

- LittleMachineShop.com 5500 HiTorque Bench Mill

- LittleMachineShop.com 6500 HiTorque Bench Mill

- SIEG SX2.7 Bench Mill

Tap & Die Set, 39-Piece Solid Round Dies

Tap & Die Set, 39-Piece Solid Round Dies